|

|

|

|

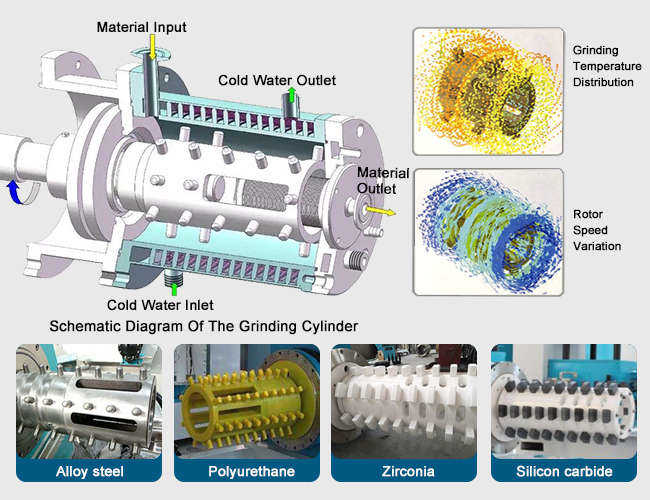

Main features ● The rod-pin horizontal sand mill is a machine suitable for ultra-fine dispersion and nano-scale grinding of water-based and solvent-based materials. ● For materials requiring no pollution, zirconia and tungsten carbide materials can be used for grinding rod pins; silicon carbide and polyurethane materials can be used for grinding barrels. ● The material enters the grinding barrel through the pre-dispersing cylinder. The improved rod pin system and the separator with large flow area can ensure high efficiency. ● Residue-free design can better solve the problem of material discharge and residue. ● Imported double-end mechanical seal is adopted, which has good sealing effect and reliable operation. ● The inner rotor and outer jacket are double cooled, and the material cooling effect is good. ● The pipeline is connected by quick connection, which is convenient for disassembly and installation.

|

Types & options

Model | IBS-5 | IBS-10 | IBS-15 | IBS-30 | IBS-50 |

Effective volume L | 5 | 10 | 15 | 30 | 50 |

Main motor power Kw | 7.5-11 | 15-30 | 30-37 | 37-45 | 55-75 |

Main shaft speed Rpm | 0-2800 | 0-1500 | 0-1200 | 0-1200 | 0-800 |

Output L/h | 30-200 | 50-300 | 100-500 | 200-1000 | 500-2000 |

Product Introduction ● The new rod pin sand mill has been improved in dispersing rod pin material, rod pin/pin pin arrangement, screen filter area, etc. Compared with the traditional sand mill, it is more suitable for nano-scale industrial production environment Grinding efficiency and finished product output have been significantly improved. ● Application: It is suitable for industrial-grade production of materials with medium and low viscosity and good fluidity with micron and nanometer particle size requirements. It is used for ultra-fine dispersion and grinding of high-performance inorganic materials such as battery materials, pharmaceutical intermediates, ceramic inkjets, ceramic color glazes, nano-alumina, aluminum nitride, silicon carbide, zirconium silicate, nano-zirconia, and pesticides. |

|

|

Working Head StructureType of Horizontal Bead Mill Working principle: The material and the grinding medium inside the cylinder are stirred by the high-speed rotating rotor, so that the solid particles in the material and the grinding medium produce stronger collision, friction and shear each other to accelerate the purpose of grinding fine particles and dispersing aggregates. With precise and reliable mechanical seal, the grinding chamber is in a sealed state to prevent the generation of air bubbles and the volatilization of additives. After grinding and dispersing, the materials are separated from the grinding media by dynamic separator and flow out from the discharge pipe. Horizontal sand mill is especially suitable for dispersing and grinding products with high viscosity and fine particle size requirements. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA- DISSOLVER®s and IDA-HORIZONTAL-BEAD-MILL®s with your products our comprehensively equipped modern laboratory is available for you. |

|