|

|

|

|

|  |

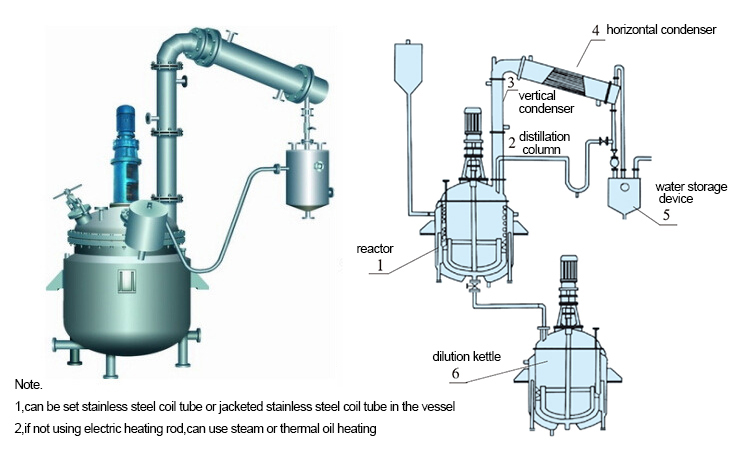

Resin is main raw materials for manufacturing plastics, in addition, it is also used for making paint, adhesion, insulating material, etc. IDA provides design and manufacturing of complete production line from lab equipment to industry large-scale equipment. IDA industry resin complete production line consists of batching kettle(droplet add kettle), reactor, vertical distillation column, vertical condenser, horizontal condenser, water knockout drum, overflow tank, pipelines, attenuation harmony kettle, filling machine, etc main devices equipped with heating device(hot oil/steam boiler), cooling system(refrigerating machine/cooling tower), vacuum system, etc to make unsaturated polyester resins, phenolic resin, epoxy resin, alkyd resin, ABS resin, etc.

Working Principle

Resin production process can be divided into the following part: raw materials metering, conveying and droplet addition, mixing and reacting (including heating, cooling, vacuumed, etc.), attenuation, cooling, filtering, filling, etc. Batching and conveying: liquid batching adopts pumps, flow meter, powder batching adopts weighing system, air conveying and manual feeding, additive batching uses weighing method.

Mixing and reacting: mixing liquid to liquid or mixing powder into liquid though mixer in a certain temperature,pressure and time.

Heating: including heating source(oil heater, boiler, etc.), heating medium(oil, hot water, steam, etc.), heating jacket and equipped pipelines, valves, pumps, etc. Normally speaking, resin reactor takes use of outer half tube jacket to heat the reactor.

Cooing: including cooling source (cooling tower, cooling mechanical group, etc. ), cooling medium(water, salt water, etc. ), cooling medium storage pool, cooling tube jacket and equipped pipelines, valves, pumps, etc. Normally speaking, resin reactor takes use of outer half tube jacket to cool the reactor down.

Condensation and vacuum: heating steam can be recycled and reused by condenser(vacuum system are optional.);condensation part includes distillation column, vertical condenser, horizontal condenser, water knockout drum, etc.Vacuum system includes vacuum pump, vacuum buffer tank, pipelines, valves, etc.

Filtering and filling: filter products after cooling, remove the sub-quality products, meter and pack the products(semiauto filling machine and automatic filling machine are optional).

Product Advantages

Various Products

IDA Equipment has rich experience in design and manufacturing resin equipment, therefore, SIEHE is able to design proper resin complete device for unsaturated polyester resins, phenolic resin, epoxy resin, alkyd resin, ABS resin emulsion, etc according to production process.

Environmentally-friendly and Easy Operation

The entire complete plant including storage of raw materials, metering, addition, medium products and finial products conveying and filling are closed and automatic, which is environmental-friendly and easy to operate.

Intelligent production with High Stability

The entire production line can realize fully enclosed automatic production, and can be programmed to realize industrial intelligence. All on-site control systems adopt explosion-proof design.

Non-standard

When resin viscosity is over 1,000,000cps, the requirement of mixing equipment will be very strict. IDA has rich experience of mixing high viscosity materials,especially for alkyd resin and acrylic resin.

Temperature Control

Temperature is one of the most important factor in resin reacting. IDA Equipment has rich design and manufacturing experience of temperature control during operation, we are confidence to control the error in +1~2°C.