|

|

|

|

As a new type of fibrous conductive agent, carbon nanotubes have higher electronic conductivity and relatively low dosage, which greatly improves the rate performance of lithium-ion batteries and prolongs the cycle life of lithium-ion batteries. It is widely used in the production and manufacture of ion power batteries. As a newly emerging conductive agent in recent years, it can not only act as a "conductor" in the conductive network, but also has an electric double layer effect to play the characteristics of a capacitor. Its good thermal conductivity is also conducive to the heat dissipation during charging and discharging of the battery. Today, the demand for lithium-ion power battery capacity and power is getting higher and higher, and carbon nanotube sand mills have become one of the main directions for the development of conductive agents. However, how to prepare carbon nanotubes into a uniformly dispersed conductive liquid and how to eliminate carbon nanotube aggregates in the conductive liquid is a major technical difficulty in the preparation of lithium-ion battery slurry. In order to help our customers solve this For the problems encountered in the production and preparation of automobile power batteries, we have done a lot of experiments in terms of production process, production equipment, formula, etc., and finally solved the technical problems of preparing uniformly dispersed carbon nanotube conductive liquid.

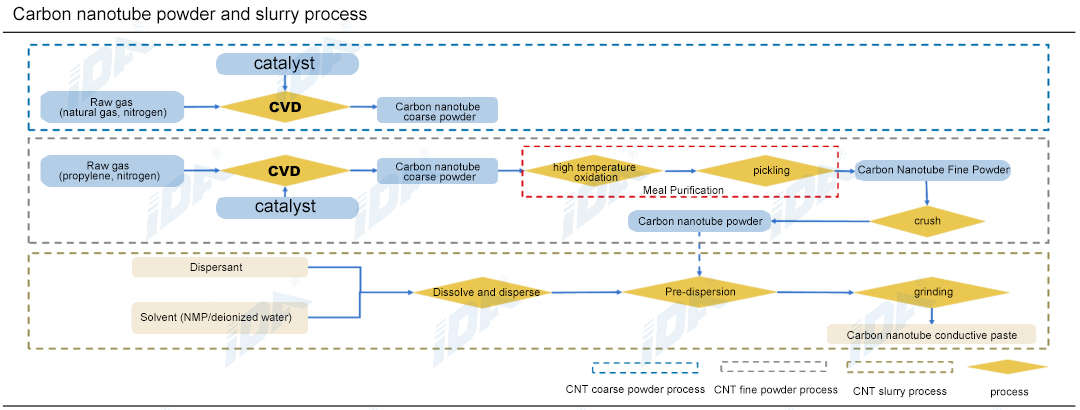

The domestic mainstream adopts the chemical vapor deposition method to prepare carbon nanotubes. At present, various carbon nanotube preparation methods such as chemical vapor deposition (CVD), graphite arc method, laser evaporation method, and hydrothermal method have been developed. Compared with other preparation methods, the chemical vapor deposition method has the advantages of easy control of the reaction process, relatively low reaction temperature, high product purity, and high single-batch yield. Domestic carbon tube enterprises all adopt chemical vapor deposition (CVD) batch production Production. The CVD method is to introduce hydrocarbons or carbon-containing oxides into a high-temperature tube furnace containing a catalyst for catalytic decomposition, and the deposited carbon self-organizes to form a cylinder of graphite sheets (carbon nanotubes) due to the presence of the catalyst.