|

|

|

|

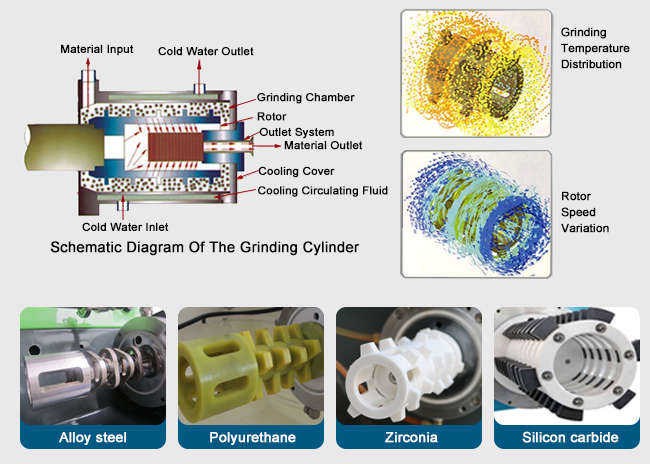

Main features ● High-performance laboratory nano-scale ultra-fine wet grinding equipment ● Continuous working mode, self-circulation system, increase production capacity ● Chamber lining material: silicon carbide, grinding rotor material: zirconia ● Grinding media without metal ion pollution, grinding materials do not change color ● Increase the cooling area and efficiency to solve the problem of difficult heat dissipation ● Quick release design of connecting pipeline, easy to install and clean ● Self-protection system for safe work, automatic shutdown function for water shortage ● Experimental results can be scaled up to guide production ● Grinding media: φ0.1-2.0mm imported ultra-fine zirconia beads

|

Types & options

| Model | Power KW | Speed rpm | Capacity Of Grinding Chamber L | Batch Size L |

| IDS-0.5 | 1.5 | 0-2800 | 0.5 | 2 |

| IDS-1 | 3 | 0-2800 | 1 | 3 |

| IDS-2 | 4 | 0-2800 | 2 | 10 |

Product Introduction ● The laboratory nano-sand mill draws on the design standards of European sand mills, with large flow rate, good temperature control capability, high energy conversion rate, and narrow particle size distribution range, especially optimized for the use of tiny grinding beads, from flexible dispersion to ultra-high energy Efficient work for grinding. ● Widely used in functional ceramics, printing inkjet, TFT/LCD color filter dispersion, lithium battery materials, thermal sensitive paper, CMP, ceramic ink, nano powder, nano color paste, food additives and other nano grinding fields. ● Rotor structure: disc, rod pin, turbine ● Abrasive parts: ceramic, polyurethane, alloy steel ● Product fineness: micron, submicron, nano |

|

|

Working Head StructureType of Horizontal Bead Mill Working principle: The motor of the equipment drives the internal feeding device to rotate at a high speed to form a negative pressure. Through self-suction, the material placed in the upper material tank is sucked and sent to the grinding chamber. The grinding medium with high filling rate in the cavity is driven by the rotation of the dial to generate irregular movements in all directions. The particles in the material are continuously collided and rubbed by the grinding medium. At the same time, the screen separates the material and the grinding medium, and the material is continuously Circulating flow from the material tank to the grinding chamber realizes the purpose of reducing the particle size and narrowing the particle size range. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA- DISSOLVER®s and IDA-HORIZONTAL-BEAD-MILL®s with your products our comprehensively equipped modern laboratory is available for you. |

|