|

|

|

|

Main features ● Hydraulic discharge machine is widely used in sealant, silicone rubber, adhesive, paste, cosmetics, paint, ink, battery glue, electronic electrode paste, mold glue, paint, ointment and other industries. ● As a non-standard chemical equipment, hydraulic discharge machine is generally used in conjunction with planetary mixer, power mixer and strong disperser. ● Equipped with a speed regulating device, the best speed can be selected according to the process requirements. ● Matching with the barrel, with a sealing ring matching the material barrel, the sealing ring is close to the barrel wall, and there is no material residue on the wall. ● Suitable for slow-flowing high-viscosity or pasty products. ● After the material is completed, it can be cleaned well, saving labor intensity. ● It has the characteristics of wide extrusion pressure range, stable discharge, reasonable structure and convenient operation..

|

Types & options

Model | YLJ30 | YLJ50 | YLJ100 | YLJ200 | YLJ300 | YLJ500 | YLJ800 | YLJ1000 | YLJ2000 |

processing volume L | 30 | 50 | 100 | 200 | 300 | 500 | 800 | 1000 | 2000 |

Power kw | 2.2 | 2.2 | 4 | 4 | 4 | 5.5 | 7.5 | 11 | 22 |

Platen diameter mm | Non-standard customization | ||||||||

Lifting stroke mm | 500 | 500 | 700 | 700 | 700 | 1000 | 1000 | 1100 | 1200 |

pressure Mpa | 12 | 12 | 25 | 30 | 45 | 60 | 80 | 100 | 180 |

Seal ring material | Silicone Rubber/Teflon | ||||||||

Lifting method | Hydraulic lift (single/double hydraulic column) | ||||||||

control method | Button or PLC control | ||||||||

preset pressure Mpa | 25Mpa | ||||||||

Product Introduction ● Hydraulic discharge machine is conventionally divided into lifting type and fixed type; it is realized by a uniquely designed hydraulic system. ● The lifting type realizes the lifting and lowering of the material under the pressure plate, and at the same time, the support frame of the barrel can be lifted and lowered independently through a separate operation, which is convenient for material receiving when the bottom is discharged. ● The fixed type generally adopts the hose outlet at the pressure plate to discharge the material, and the bottom valve can also be used to discharge the material. |

|

|

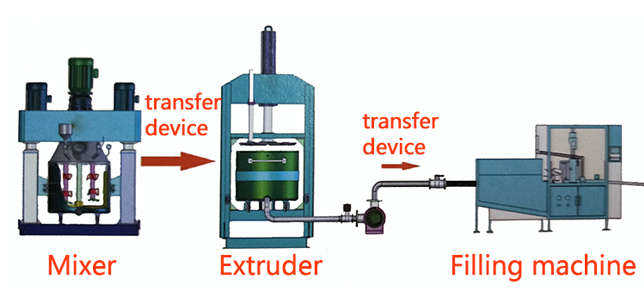

Working Head StructureType of Hydraulic Discharge Machine Working principle: The hydraulic discharge machine is a matching discharge equipment after the mixing of the planetary mixer and the multi-shaft vacuum mixer. It is used for discharging and sub-packaging. Exclusive presser; the extruder is equipped with a sealing ring that matches the barrel. During the extrusion process, the sealing ring is close to the barrel wall to help the high-viscosity material to be emptied from the container, and there is no material residue on the wall, and then metering, Dispensing, filling; the pressure and the height of the platen can be adjusted, and two options of pneumatic and hydraulic are available. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA-DISSOLVER®s and IDA-DISCHARGE-MACHINE®s with your products our comprehensively equipped modern laboratory is available for you. |

|