|

|

|

|

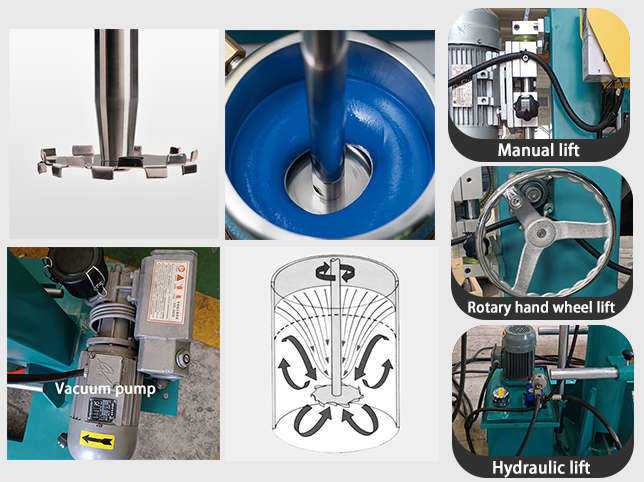

Main features ● Suitable for industrial mass production. ● Frequency conversion speed regulation, digital display. ● The electric lifting method is stable, convenient, and the structure is firm and durable. ● High-speed motor, strong power. ● It adopts stepless frequency conversion speed regulation method, which can run for a long time, with stable operation and low noise. ● Dispersing discs of different specifications and forms can be replaced according to the process characteristics. ● The design of electric turning cylinder can automatically dump the material out. ● Jacketed double-layer stainless steel tank, electric heating design, with temperature measuring device. ● According to different materials, the motor can be explosion-proof or ordinary. ● According to the process requirements, vacuum type, heating type, one machine with multiple cylinders, etc. can be selected.

|

Types & options

| Model | Motor power kw | Speed rpm | Lifting height mm | Processing capacity L | Disc diameter mm | Pump power kw |

| IGF4 | 4 | 0-1450 | 600 | 50-200 | 150 | 0.55 |

| IGF5.5 | 5.5 | 0-1450 | 800 | 80-250 | 200 | 0.55 |

| IGF7.5 | 7.5 | 0-1450 | 900 | 100-300 | 250 | 0.75 |

| IGF11 | 11 | 0-1450 | 900 | 100-400 | 250 | 0.75 |

| IGF15 | 15 | 0-1450 | 1000 | 150-500 | 300 | 0.75 |

| IGF18.5 | 18.5 | 0-1450 | 1100 | 200-800 | 300 | 1.1 |

| IGF22 | 22 | 0-1450 | 1100 | 200-1000 | 300 | 1.1 |

| IGF30 | 30 | 0-1200 | 1200 | 300-1500 | 350 | 1.1 |

| IGF37 | 37 | 0-1200 | 1300 | 400-2000 | 400 | 1.5 |

| IGF45 | 45 | 0-1200 | 1300 | 500-2500 | 450 | 1.5 |

| Motor working environment form | Explosion-proof/non-explosion-proof | |||||

| Other specifications: can be designed and customized according to customer needs | ||||||

Product Introduction ● The electric heating stainless steel dispersing cylinder raises the temperature of the heat-conducting oil or water to the required temperature through the electric heating device, and transfers the heat to the material in the reaction kettle to achieve the material reaction temperature. ● The electric heating cylinder is a double-layer stainless steel cylinder. The heating medium is usually heat-conducting oil or water, and is heated by an electric heating rod. It is used for storage or stirring of materials that need to be kept warm or heated. |

|

|

Working Head StructureType of Dispersing Machine Working principle: The serrated circular dispersing disc of the disperser disperses at high speed in the container to complete the process of solid-liquid dispersion, wetting, depolymerization and stabilization. The slurry is in a rolling annular flow, generating a strong vortex, and the particles on the surface of the slurry descend to the bottom of the vortex in a spiral shape; a turbulent zone is formed at 2.5-5mm from the edge of the dispersion plate, and the slurry and particles are subjected to strong shear and impact; With two streams, the slurry is fully circulated and turned; the lower part of the dispersing disc of the disperser is in a laminar flow state, and the slurry layers with different flow rates diffuse each other to play a role in dispersion. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA-DISSOLVER®s and IDA-DISPERSING-MACHINE®s with your products our comprehensively equipped modern laboratory is available for you. |

|