|

|

|

|

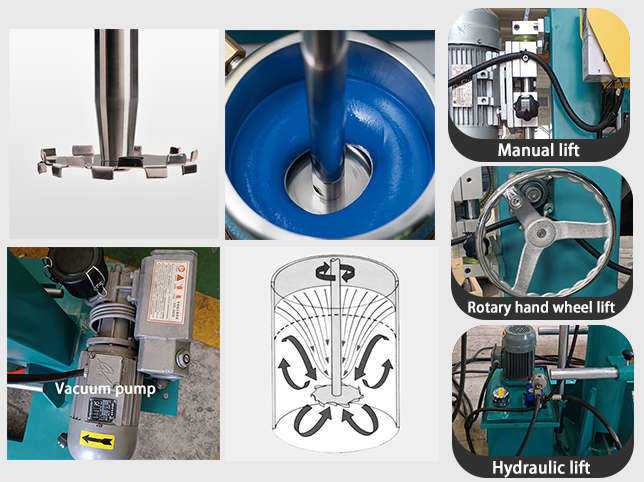

Main features ● Frequency conversion speed regulation, digital display. ● Lifting method: manual lifting, electric lifting, hydraulic lifting ● Closed design of cover and cylinder, equipped with vacuum system. ● Vacuum defoaming, no bacterial pollution, no leakage, reduce material loss. ● Automatic control, automatic temperature and pressure feedback system to ensure stability. ● The parts of the vacuum disperser in contact with the material are made of stainless steel. ● Solutions can be customized according to user requirements, and the motor can be equipped with explosion-proof type. ● Clamping device for fixing the dispersion tank. ● The dispersing element is easy to replace and clean, reducing the cost.

|

Types & options

| Model | Motor power kw | Speed rpm | Lifting height mm | Processing capacity L | Disc diameter mm | Pump power kw | Vacuum degree Mpa |

| IGF4 | 4 | 0-1450 | 600 | 50-200 | 150 | 0.55 | ≤-0.09 |

| IGF5.5 | 5.5 | 0-1450 | 800 | 80-250 | 200 | 0.55 | ≤-0.09 |

| IGF7.5 | 7.5 | 0-1450 | 900 | 100-300 | 250 | 0.75 | ≤-0.09 |

| IGF11 | 11 | 0-1450 | 900 | 100-400 | 250 | 0.75 | ≤-0.09 |

| IGF15 | 15 | 0-1450 | 1000 | 150-500 | 300 | 0.75 | ≤-0.09 |

| IGF18.5 | 18.5 | 0-1450 | 1100 | 200-800 | 300 | 1.1 | ≤-0.09 |

| IGF22 | 22 | 0-1450 | 1100 | 200-1000 | 300 | 1.1 | ≤-0.09 |

| IGF30 | 30 | 0-1200 | 1200 | 300-1500 | 350 | 1.1 | ≤-0.09 |

| IGF37 | 37 | 0-1200 | 1300 | 400-2000 | 400 | 1.5 | ≤-0.09 |

| IGF45 | 45 | 0-1200 | 1300 | 500-2500 | 450 | 1.5 | ≤-0.09 |

| Other specifications: can be designed and customized according to customer needs | |||||||

| Motor working environment form | Explosion-proof/non-explosion-proof | ||||||

Product Introduction ● Vacuum dispersion machine is suitable for: paint, dyestuff, pigment, paint, ink, adhesive, resin, ointment, cosmetics, paper, food, rubber and plastic, composite materials, insulating materials, magnetic materials, other color paste and other chemical industry products of liquid-solid wet dispersion, grinding, mixing, homogenization, mixing, dissolving processing equipment. ● It is used in the process of multi-bubble materials and volatile solvents. By vacuuming, the materials are dispersed in the vacuum container to reduce the volatilization of bubbles and solvents. The material is defoamed quickly. |

|

|

Working Head StructureType of Dispersing Machine Working principle: Through the high-speed rotation dispersing disc, the materials will become in annular form flow, resulting in strong vortex flow, which descend down to the bottom of the vortex in spiral state. During the process, materials are dispersed, dissolved, mixed and emulsified efficiently due to the strong shearing crash and friction among the particles.The equipment is equipped with a randomly lifted airtight drum lid, which can be absolutely closed with the drum to achieve a high vacuum level and effectively avoid solvent evaporation; the drum lid is equipped with a sight glass light to observe the dispersion status in real time; it is equipped with a sanitary manhole, which can be used for equipment cleaning and refilling. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA-DISSOLVER®s and IDA-DISPERSING-MACHINE®s with your products our comprehensively equipped modern laboratory is available for you. |

|