|

|

|

|

Main features ● It has a wide range of applications, and can adjust the protrusion of the roller according to the viscosity of the material. It can be used for products with high, medium and low viscosity. ● Hydraulic control, higher efficiency, 3 times the production efficiency of ordinary three-roller machines. ● The basic feeding, discharging and fineness control of the machine are all controlled by hydraulic pressure, with a high degree of automation, easy operation and safe use. ● The roller is cast with special alloy material, with high strength, high hardness and high wear resistance on the surface. ● The temperature rise is small and the product is stable. The center of the roller can pass cooling water during the operation of the equipment, which has a good cooling effect. The normal temperature rise is less than 10 ℃, and the product quality is guaranteed. ● Non-standard custom explosion-proof type can be provided; automatic dumping can be realized with dumping. ● Optional PLC control to control roller gap, pressure, water temperature, etc. ● There is a fine-tuning system (four fine-tuning devices), which is widely used in high and low viscosity industries.

|

Types & options

| Model | YS260 | YS400-800 | YS400-1000 | YS400-1300 | |

| Roller diameter (mm) | 260 | 400 | 400 | 400 | |

| Working length(mm) | 650 | 800 | 1000 | 1300 | |

Height of discharge from the ground (mm) | 750 | 690 | 690 | 690 | |

| Output (L/h) | 180~250 | 250~350 | 300~400 | 360~450 | |

| Roll rotating speed (r/min) | Slow | 58 | 32 | 32 | 32 |

| Middle | 153 | 128 | 128 | 128 | |

| Fast | 408 | 400~450 | 400~450 | 400~450 | |

| Main motor power (KW) | 22 | 37 | 45 | 55 | |

| Total pressure of hydraulic system (Mpa) | 6.3 | 6.3 | 6.3 | 6.3*2 | |

| Hydraulic power (KW) | 1.5 | 1.5 | 1.5 | 1.5*2 | |

| Weight (kg) | 2000 | 4800 | 5000 | 5200 | |

| Overall size (mm) | 1558x1280x1200 | 2150x1750x2295 | 2350x1700x2295 | 2650x1750x2295 | |

Product Introduction ● The equipment can control the machine according to the user's optional Siemens programmable logic controller (PLC) for automatic production or remote control. It is also equipped with a touch screen that simulates a graphical interface, which is easier for operators to master as soon as possible, making the machine operation more accurate and stable, and can record production data and implement data reproducibility. ● The fine-tuning device of the CNC hydraulic three-roll grinder is controlled by a servo motor, and the roller gap adjustment is more accurate and the synchronization is higher. Especially suitable for the processing of medium and low viscosity materials. The operator only needs to choose various pre-set formulas (including roller gap, pressure, water temperature, etc.) to operate in sequence, which is very convenient. |

|

|

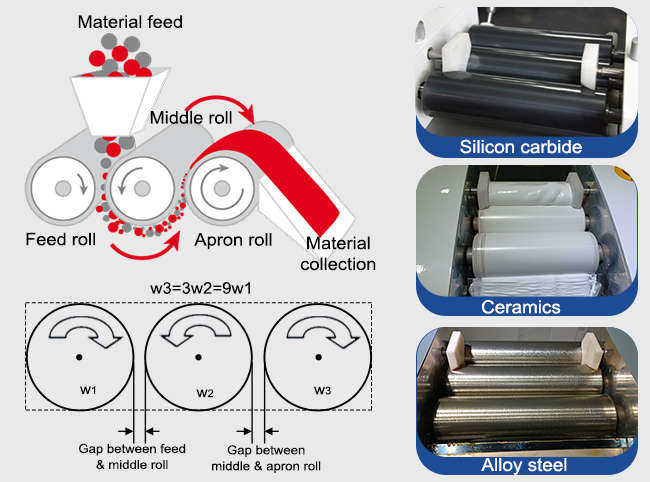

Working principle of Three Roll Mill Working principle: The hydraulic three-roller grinder consists of three rollers, which are mounted on a frame and are directly driven by an electric motor. Generally, the rotation directions between the rollers are different, the front roller rotates forward, and the middle roller rotates backward. Roller speed: the front roller is fast, the rear roller is slow. The middle roller is fixed, the front and rear rollers are mounted on the slideway, and there is a spring device to adjust the distance between the front and rear rollers and the middle roller by hydraulic pressure. The material enters between the rear roller and the middle roller, is squeezed by the roller, and the product particles become thinner, and then taken out by the fast roller. The end of the fast roller is equipped with a scraper to separate the material from the roller and fall into the collection bucket. Due to the heat generated in the grinding process, the center of each roller is designed as a hollow structure, which is cooled by water to ensure product quality. |

|

Laboratory trials In order to be able to demonstrate the advantages and effectiveness of our IDA-DISSOLVER®s and IDA-THREE-ROLL-MILL®s with your products our comprehensively equipped modern laboratory is available for you. |

|